A recent article in New Scientist, and the peer reviewed paper behind it [1], opened my eyes to the staggering amount of wood from managed forests that goes up in smoke, if not immediately then after quite a short lifetime as something useful. This is a shame, given the potential for using wood to store carbon. The article includes a rather fine flow digram of what happens to the wood we cut at the global level. I have compared these figures to what happens in the UK using data produced for the government by Forest Research [2]. A great deal less of our wood is used immediately for fuel, but rather more of it is used for short lived uses like fencing or paper/packaging. How can we increase the value of wood for carbon storage?

Flow diagram of how wood is used globally.

To start with, more than half the wood taken from forest is used as fuel. Also, most of the waste generated from processing is used as fuel. Some of the wood ends up as sawn timber which can be used to make things, or as wood based panels such as plywood, chipboard and OSB (Oriented strand board). I think wood fibre insulation panels come into this category too. These can be regarded as long lived products. The other products last only a few years, up to a decade or so.

The UK uses less wood for fuel, more for low grade uses like fencing.

Needless to say the categories used in [2] do not quite match but I have done my best to compare like with like. This chart shows the percentage of total wood production by category.

|

| Global data from [1] compared with UK data from [2]. Paper/packaging includes just the virgin wood used for paper production - addition pulp comes from recycling. |

Here in the UK a great deal less of our wood ends up as fuel, at least to start with. We use a higher proportion for long lived uses such as construction and wood-based panels but this still adds up to less than a third. We use a lot more than the global average for low value products such as fencing and paper/packaging - for the UK data this includes palettes. In this country most paper products will ultimately be recycled or composted rather than used for energy.

In the UK hardwood is mostly used for fuel but it was not always thus.

|

| Comparing uses of softwood and hardwood products by percentage of production. The anount of softwood produced is 13 times the amount of hardwood. Data from [2] |

In the UK we produce a lot more softwood than hardwood: 13 times as much. Three quarters of the softwood produced comes from Scotland. Nearly 90% of the hardwood comes from privately owned forest, presumably for love and biodiversity rather than commercial return.

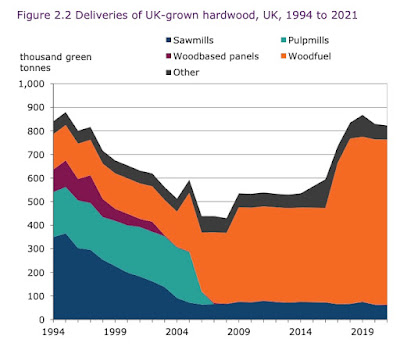

Hardwood grows slowly and these days 85% of is used as fuel. This is a huge change over the last few decades. As of the year 2000, only a quarter was used as fuel - a third went to sawmills and another third went to paper mills. The proportion of softwood used for fuel has also increased, from basically zero in 2000 up to 15% now. Some of this wood fuel is used domestically - biomass stoves and boilers are far more popular now than they used to be - but the greater part goes to feed power stations.

|

| Initial use of hardwood grown in the UK from 1994 to 2021. From [2]. Much of the wood that previously was sawn or used to make panels is now used for fuel |

Most of the wood processed in this country is locally grown. We export 2% of our softwood and import about twice as much. However we import a great deal of wood already processed in the form of biomass fuel pellets.

Power stations with CCS are still at the pilot stage.

There are a lot of little biomass power stations producing electricity, especially in Scotland. However you probably know the largest, by far, is Drax. By itself it provides three quarters of our total biomass electricity capacity [3]. It does not only use wood - it uses any sort of plant biomass and a lot of this is imported. The electricity produced from Drax and other biomass power stations counts for about a quarter of our renewable electricity (as of 2020).

Drax has long term plans to upgrade its biomass power plant to capture and store the CO2 generated from burning the plant material. So far they have got as far as a couple of pilots for the capture technology [4]. The company wants more assurance from the government before going ahead with installing capture technology on the main facility [5].

In practice, biomass fuel for power stations is not carbon neutral to start with

If CCS is installed, and the biomass fuel for the power station were itself carbon neutral, then this would count as negative emissions. But is the biomass fuel carbon neutral? A great deal depends on whether the power station only uses 'waste' wood or if it's huge demand triggers deforestation. When trees are felled and used as fuel there are immediate emissions and even if trees are replanted or allowed to grow this takes a long time. This means the 'sustainable' forest actually stores a lot less carbon, both initially and on average, than the original forest.

If only waste wood is used, then there should be no need to cut down new forest. However when whole trees are cut down and entirely turned into wood pellets it is hard to imagine this is 'waste' wood [6]. Given the increase in the proportion of UK wood now turned into fuel, it seems the definition of 'waste' is somewhat fluid even in locally produced material.

BECCS versus wood in construction

In this post we have discussed two ways to store carbon using wood from sustainable forests. Neither is a panacea.

In long-lived wood products such as construction materials, furniture and homeware.

- Is not permanent - some products only last a few decades. After that, possibly the material could be recycled a few times, for example as wood fibre products. If it has not been treated with toxic chemicals it could then be composted.

- Little new infrastructure is needed, though we might need a few more saw mills as well as more forest.

- Can be used instead of materials with higher emissions such as steel, bricks and plastics.

BECCS - Biomass Energy with Carbon Capture and Storage

- Theoretically this would be permanent (depending on the storage mechanism).

- Would need expensive new infrastructure for capturing, transporting and storing the CO2.

- It seems impossible to adequately regulate the biomass supply and ensure it really is carbon neutral.

Either approach will mean increasing demand for wood and it is critical that this does not come from cutting down existing forest. Doing that triggers an immediate hit of carbon emissions that is never fully recovered. However, if we convert land from pasture to woodland, there is a net increase in carbon storage over time - it takes a few decades to grow new woodland. This is not a quick fix and we need to manage demand carefully.

[1] The carbon costs of global wood harvests ( Liqing Peng , Timothy D. Searchinger, Jessica Zionts & Richard Waite in Nature) 2023

[2] Forestry Statistics 2022 - Chapter 2: Timber. (www.forestresearch.gov.uk) 2022

I'm surprised they didn't use a Sankey diagram for the flow chart. I'm also surprised that the UK uses a higher proportion of timber for construction than the global average - given our preference for masonry buildings and reluctance (in England and Wales at least) to use timber frame for volume housebuilding.

ReplyDeletePresumably you didn't mention the big *benefit* of using wood or pellets as fuel - as a low-carbon alternative to fossil fuels for heating - because that is well documented elsewhere.